Production Supervisory Roles—Your First Leadership Position

Table of Contents

The Invisible Backbone: What Makes Good Factories Great?

Visit two identical automotive assembly facilities with identical equipment, same company brand, and same products. One produces 500 perfect units daily with happy workers. The other struggles to hit 400 units with frequent quality issues and staff turnover.

The difference? Leadership. Specifically, shift supervisors.

A good supervisor is the difference between a factory running smoothly and chaos. They’re the bridge between worker operators and management. They solve problems, develop people, ensure safety, and drive continuous improvement. This is your opportunity for true leadership—your first step from individual contributor to leader.

Modern manufacturing demands supervisors who understand both operational excellence and people development. This is no longer about barking orders; it’s about intelligent, empathetic leadership.

What Exactly Does a Shift Supervisor Do?

Let me paint a realistic picture of a day in the life of a shift supervisor.

Akshay, Shift Supervisor at an Automotive Component Facility (Day Shift: 6:00 AM – 2:00 PM)

5:45 AM: Akshay arrives 15 minutes early. He reviews the previous shift’s handover report:

- Production targets hit: 98% (goal: 100%)

- Quality issues: 2 batches flagged, root cause under investigation

- Equipment status: One CNC machine had minor vibration (scheduled maintenance)

- Team notes: Two operators called in sick, emergency contractors filled gaps

- Safety incidents: None

- Morale notes: Team appreciated the end-of-shift recognition program

6:00 AM: Pre-shift meeting with his team of 12 operators and technicians:

- Reviews daily targets (450 units, 99% quality)

- Discusses previous shift learning (“That humidity issue that caused defects yesterday—we adjusted controls, so watch for normal production today”)

- Recognizes high performers from previous shift

- Discusses any equipment concerns or changes

- Emphasizes safety focus for the day

- Addresses any personal concerns or requests

6:30 AM – 9:00 AM: Floor time

Akshay walks the production line systematically:

- Observes each operator’s technique (looking for safety issues or quality concerns)

- Checks equipment readings

- Verifies materials are stocked correctly

- Talks informally with operators about their work, concerns, or suggestions

- Addresses a quality issue: One product assembly looks misaligned. He works with the operator to identify the issue (fixture not seated correctly). Fix takes 5 minutes; prevented dozens of defects.

- Receives an alert: Equipment showing unusual temperature. Akshay consults with the maintenance technician, decides to monitor closely but continue production. Documents the issue.

9:00 AM – 10:30 AM: Administrative work

- Reviews production data dashboard: Currently at 105 units (pace is excellent, on track for 450)

- Responds to messages from production manager (his boss)

- Reviews quality inspection reports

- Completes incident documentation from previous shift

- Plans for equipment maintenance window

- Reviews feedback from workers (via suggestion system)

10:30 AM – 12:00 PM: More floor time

- Production is smooth; quality is excellent

- Akshay spends time with a newer operator who’s struggling with one assembly step. He provides coaching, breaks down the procedure, helps the operator understand why that step matters (reducing defects, improving efficiency)

- He notices another operator is exceptionally fast while maintaining quality. Makes a mental note—potential for promotion to Lead role

- Addresses a safety concern: One worker not using proper PPE consistently. Akshay has a conversation (not confrontational, educational), explains the “why,” ensures understanding

- Facilitates a quick problem-solving session: Production pace is slightly behind target. Team brainstorms—realizes there’s a minor bottleneck in quality inspection hand-off. Suggests a small change in sequencing. Implements. Production speed improves.

12:00 PM – 1:30 PM: More administrative and planning

- Updates the production log (targets met, quality excellent)

- Identifies an operator who’s ready for advancement; plans a conversation with HR about Lead role opportunity

- Plans the next week’s training schedule (2 new operators joining)

- Reviews maintenance request list

- Prepares handover notes for next supervisor (evening shift)

1:30 PM – 2:00 PM: Shift end

- Conducts final floor walk (ensuring everything is clean, safe, ready for next shift)

- Meets with evening shift supervisor, provides detailed handover

- Reviews: 455 units produced (100.3% of target), 99.8% quality, zero safety incidents, three operators recognized for excellence

What This Day Shows:

Notice what Akshay did:

- Managed people (coached, recognized, developed)

- Solved problems (identified equipment issue, quality issue, process improvement)

- Ensured safety and compliance (monitored procedures, addressed PPE issue)

- Made decisions (when to maintain equipment, how to adjust processes)

- Developed talent (spotted promotion candidate, trained new operator)

- Communicated (shift meeting, handover, manager updates)

This is modern supervisory work. It’s not about control; it’s about leadership, enabling, and continuous improvement.

Key Responsibilities of a Shift Supervisor

Production Management (30% of role):

- Meet daily production targets

- Optimize workflow efficiency

- Allocate operator assignments based on skill

- Monitor equipment performance

- Manage material flow

- Ensure on-time production

- Report production metrics

Quality Assurance (25% of role):

- Maintain quality standards

- Review quality data and trends

- Identify and address quality issues

- Collaborate with QA team

- Implement corrective actions

- Create zero-defect culture

- Document quality incidents

Team Leadership (25% of role):

- Manage 10-20 operators/technicians

- Assign work and set expectations

- Provide training and development

- Conduct performance reviews

- Address performance issues (coaching and discipline)

- Recognize and reward good work

- Build team cohesion

- Handle conflicts and complaints

Safety & Compliance (15% of role):

- Ensure all safety procedures are followed

- Investigate safety incidents

- Maintain safety records and compliance

- Conduct safety meetings

- Enforce use of protective equipment

- Create safety-conscious culture

- Report hazards

Process Improvement (5% of role):

- Identify bottlenecks and inefficiencies

- Suggest improvements

- Participate in kaizen/lean initiatives

- Share best practices

- Mentor continuous improvement mindset

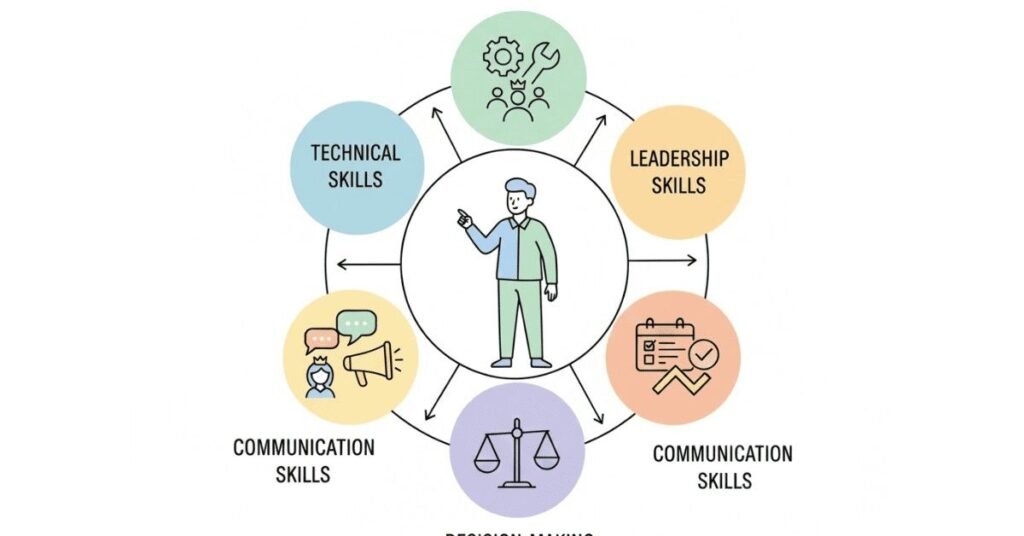

Skills You Need to Be an Excellent Supervisor

Technical Skills:

- Deep understanding of production processes (you know the “why” behind procedures)

- Equipment knowledge (can diagnose issues)

- Quality standards interpretation (can teach and verify)

- Production planning basics (can balance capacity and demand)

- Data interpretation (understand production dashboards)

Leadership Skills:

- Coaching ability: Help operators improve, not just criticize

- Decision-making: Make fair, timely decisions

- Problem-solving: Diagnose root causes, implement solutions

- Communication: Explain clearly, listen actively

- Conflict resolution: Handle disagreements professionally

- Motivation: Inspire team to excel

- Accountability: Own outcomes, don’t blame others

Emotional Intelligence:

- Self-awareness (understand your impact)

- Empathy (recognize what operators are experiencing

- Relationship management (build trust)

- Social awareness (read situations accurately)

- Impulse control (stay calm under pressure)

Practical Skills:

- Time management (multiple priorities simultaneously)

- Documentation (accurate record-keeping)

- Multitasking (handle production + people + compliance)

- Stress management (factory can be chaotic)

Physical capability (stand/walk 8+ hours daily)

Salary Expectations for Shift Supervisors

Entry to Supervisory Role (First-time Supervisor):

₹25,000 – ₹38,000/month

(This is promotion from Senior Operator/Lead role)

With Performance Bonuses & Allowances:

- Base: ₹30,000

- Shift allowance: +₹2,000-3,000

- Performance bonus: +₹3,000-6,000

- Leadership bonus: +₹1,500-2,500

- Actual take-home: ₹36,500-44,500/month

Senior Shift Supervisor (3-5 Years Experience):

₹38,000 – ₹55,000/month

Assistant Manager / Production Supervisor:

₹50,000 – ₹75,000/month

Production Manager (5-10 Years):

₹65,000 – ₹1,00,000+/month

Sector-Based Salary Variation:

Sector | Shift Supervisor Start | Production Manager (5 yrs) |

Automotive | ₹28,000-38,000 | ₹70,000-95,000 |

Electronics | ₹30,000-40,000 | ₹75,000-1,00,000 |

Pharmaceuticals | ₹26,000-36,000 | ₹65,000-85,000 |

Food Processing | ₹22,000-30,000 | ₹50,000-70,000 |

Steel & Metals | ₹28,000-38,000 | ₹68,000-90,000 |

Notice: Supervisor salary jumps significantly from operator/technician roles. The ₹8,000-15,000 jump from operator to supervisor is substantial. And that’s just the base—with bonuses, a high-performing supervisor can easily earn ₹40,000-50,000+/month within 2-3 years of promotion.

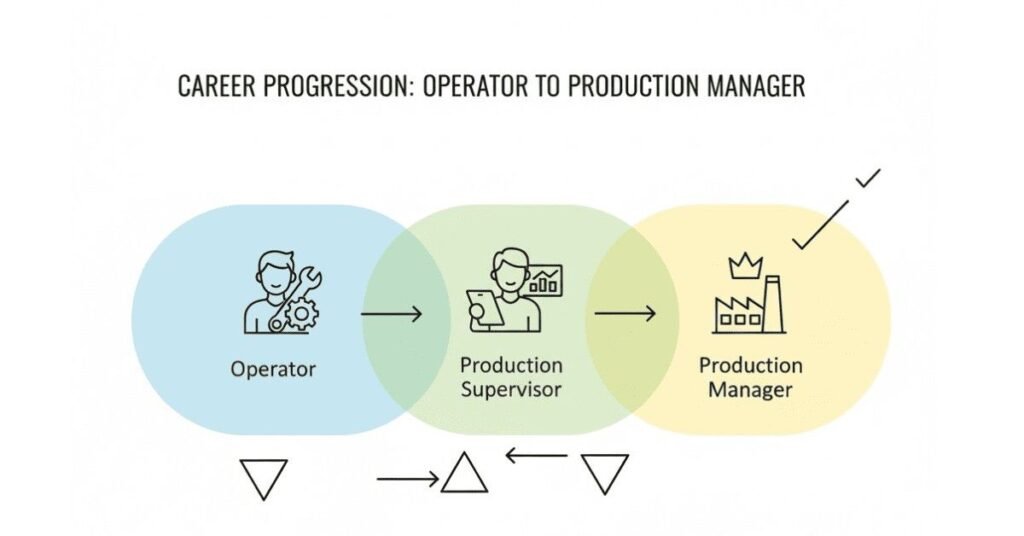

The Path to Supervisory Role: Realistic Timeline

Year 1-2: Operator/Technician Role (₹15,000-25,000)

- Master core responsibilities

- Demonstrate reliability

- Show initiative

- Build credibility with supervisors

Year 2-3: Lead/Senior Operator (₹22,000-32,000)

- Mentor newer operators

- Take on informal leadership

- Solve problems independently

- Show supervisory potential

Year 3-4: Promoted to Shift Supervisor (₹28,000-40,000)

- Formal leadership responsibility

- First-time management of team

- Learning curve: steep but achievable

- Mentorship from production manager

Year 5+: Senior Supervisor / Manager Roles (₹50,000+)

- Expanded responsibility (multiple shifts/departments)

- Strategic thinking

- Development of other supervisors

- Senior management track

Timeline: Operator to Supervisor typically takes 3-4 years if you’re deliberate about development and show leadership potential.

How to Prepare for Supervisory Role BEFORE Promotion

Don’t wait until you’re promoted to start developing leadership. Start now:

Develop Leadership Mindset:

- Volunteer for small leadership tasks (mentoring, mini-project leading)

- Help solve problems beyond your direct responsibility

- Take ownership of outcomes, not just tasks

- Think about “how do we” not just “what do I”

Improve Technical Knowledge:

- Master procedures deeply (know the why)

- Understand equipment maintenance basics

- Learn about quality systems

- Understand production planning

Develop Communication Skills:

- Practice explaining technical concepts clearly

- Learn to listen actively (don’t interrupt)

- Develop written communication (reports, emails)

- Present ideas to supervisors

- Facilitate group discussions

Build Emotional Intelligence:

- Notice how others react to situations

- Develop empathy (understand others’ perspectives)

- Manage your emotions (stay calm under pressure)

- Build relationships (not just transactions)

- Give and receive feedback gracefully

Show Initiative:

- Identify problems and suggest solutions (don’t just report)

- Take on challenging projects

- Learn new skills proactively

- Step up when needed (without being asked)

Follow through on commitments

The Transition: From Individual Contributor to Leader

The shift from operator to supervisor is challenging. You’re suddenly the “boss” to former peers. Here’s what to expect:

Challenges:

- Peer Relationship Change

- Yesterday’s peers are now your team members

- Some will resist your authority

- Balance: Be fair but firm

- Yesterday’s peers are now your team members

- Decision-Making Pressure

- You now make choices affecting 10+ people

- Your decisions have financial/quality implications

- Learning curve: steep initially, manageable with support

- You now make choices affecting 10+ people

- Time Management

- Production targets + people management + compliance

- Constant interruptions

- Requires multitasking and prioritization

- Production targets + people management + compliance

- Conflict Handling

- Managing performance issues with former peers (awkward)

- Mediating disputes between team members

- Enforcing rules others don’t like

- Managing performance issues with former peers (awkward)

How to Navigate Successfully:

- Establish respect early: Be competent, fair, and consistent

- Support former peers: Show that promotion doesn’t make you arrogant

- Learn quickly: Ask questions of more senior supervisors

- Communicate clearly: Explain the “why” behind decisions

- Be consistent: Same standards for everyone

- Show appreciation: Recognize good work genuinely

- Admit mistakes: Build trust by being honest

Mentor others: Help others develop like someone developed you

Why This Progression Matters

Going from operator (₹15,000) to supervisor (₹30,000+) in 3-4 years represents a 100% salary increase. Over 5 years, you’re earning ₹3,60,000/month vs. ₹1,20,000/month as operator—that’s ₹14,40,000 additional income over 5 years.

More importantly, you’re building a career. You’re not just earning more; you’re developing leadership capability that opens doors to plant manager, operations director, or even manufacturing leadership roles globally.

The Bottom Line: Supervisory Path is Your Career Accelerator

If you enter manufacturing as an operator and perform well, supervisory role awaits within 3-4 years. This is your genuine, structured pathway to leadership without needing an MBA or separate degree. Manufacturing rewards capability and performance. Show both, and advancement follows.