EHS Officer—The Safety Guardian

Table of Contents

The Person Who Prevents Disasters: EHS Officer

Manufacturing involves hazards: heavy machinery, chemicals, high temperatures, electrical systems, noise. One safety failure can cause serious injury or death.

EHS Officers (Environment, Health & Safety) are responsible for preventing these disasters. They earn ₹30,000-48,000/month as entry-level coordinators, advancing to ₹60,000-1,00,000+/month within 6-8 years as managers or directors.

What EHS Officers Actually Do:

Sneha, EHS Officer at a chemical manufacturing facility:

Monday: Incident Investigation

Worker got minor chemical burn—not serious, but any incident gets investigated.

Sneha:

- Interviews worker: What happened?

- Reviews work procedure: Did worker follow correct steps?

- Inspects site: Were safety guards in place?

- Checks PPE: Was protective equipment available and used?

- Finds: Worker wasn’t wearing gloves (didn’t realize they were needed)

- Root cause: Procedure wasn’t clear; previous worker did same thing without incident (luck)

- Action: Updates procedure with clearer guidance, adds warning sign, conducts training

Wednesday: Safety Audit

Quarterly internal audit of all safety procedures:

- Walks entire facility systematically

- Checks fire extinguishers (properly located, charged, current inspection tags?)

- Verifies emergency exits (unlocked, clearly marked, unobstructed?)

- Checks PPE availability (helmets, gloves, eye protection accessible where needed?)

- Inspects safety equipment (guardrails secure, warning signs visible?)

- Interviews workers: “Do you feel safe? Any concerns?”

- Documents findings: 3 minor issues (PPE not restocked after recent use, one guardrail loose, emergency contact info outdated)

- Issues corrective action report: All issues fixed within 2 days

Thursday: Regulatory Compliance Review

Manufacturing must comply with OSHA standards, environmental regulations, state safety laws. Sneha:

- Reviews latest regulatory updates (do regulations change?)

- Audits compliance: Are we following regulations?

- Finds: New regulation requires monthly inspection of pressure vessels

- Implements: Adds monthly inspection schedule, trains personnel

- Documents: Maintains compliance records

Friday: Near-Miss Program Review

Company has a “near-miss” program: Workers report incidents that almost happened but didn’t.

Sneha reviews this week’s near-misses:

- “Material almost fell from shelf onto worker” (shelf was overloaded)

- “Worker almost slipped on wet floor” (spilled liquid not cleaned promptly)

- “Equipment almost ran without safety guard” (worker forgot to engage guard)

For each:

- Investigates root cause

- Implements corrective action (reduce shelf load, mop spills immediately, enforce guard verification)

- Communicates lessons to all workers

- Tracks trends (if patterns emerge, addresses systematically)

Ongoing: Safety Culture Development

- Conducts monthly safety training (new procedures, refreshers, hazard awareness)

- Maintains safety bulletin board (regulations, incident reports, safety tips)

- Organizes safety committee meetings (workers + management discussing safety)

- Recognizes safety achievements (workers without incidents praised publicly)

- Communicates with management on safety metrics

Result: Facility has gone 2 years without serious incident. Workers feel safe. Regulatory compliance verified. Insurance premiums lower.

Key Responsibilities of EHS Officer

Safety Program Management (30%):

- Develop safety policies and procedures

- Implement safety programs

- Maintain safety equipment

- Coordinate safety training

- Manage incident prevention

Risk Assessment & Management (25%):

- Identify workplace hazards

- Assess risk levels

- Implement hazard controls

- Monitor effectiveness of controls

- Update as conditions change

Incident Investigation (20%):

- Investigate accidents and near-misses

- Identify root causes

- Implement corrective actions

- Prevent recurrence

- Document all findings

Regulatory Compliance (15%):

- Maintain compliance with OSHA standards

- Follow environmental regulations

- Keep required documentation

- Prepare for regulatory audits

- Stay current on changing regulations

Training & Communication (10%):

- Conduct safety training

- Communicate hazards and procedures

- Educate workers on safety importance

- Create safety culture

Build worker engagement

Technical Skills You Need

Core EHS Skills:

- Safety Standards Knowledge (Critical)

- OSHA standards (U.S. standards applicable to global companies)

- Industry-specific standards (varies by sector: pharma, automotive, chemicals)

- Environmental regulations

- Health standards (ergonomics, noise exposure, chemical safety)

- Why: Your job is ensuring compliance

- Learning: OSHA training courses (40-60 hours)

- Risk Assessment Methodologies (Important)

- Hazard identification techniques

- Risk assessment matrices

- FMEA (Failure Mode & Effects Analysis) applied to safety

- Severity-probability assessment

- Why: Systematically identify and reduce risks

- Learning: Training courses (30-40 hours)

- Incident Investigation (Important)

- Root cause analysis techniques (5-why method, fishbone diagrams)

- Investigation procedures

- Documentation

- Corrective action planning

- Why: Learn from incidents, prevent recurrence

- Learning: Training courses (20-30 hours)

- Environmental Knowledge (Increasingly Important)

- Environmental regulations (waste disposal, emissions, water discharge)

- Sustainability principles

- Environmental impact assessment

- Why: “E” in EHS increasingly important as sustainability emphasized

- Learning: Environmental management courses (30-50 hours)

- Workplace Health & Ergonomics (Important)

- Occupational health standards

- Ergonomic assessments

- Noise, lighting, ventilation requirements

- Chemical hazard communication

- Why: Worker health is critical EHS responsibility

- Learning: Occupational health courses (30-40 hours)

Additional Technical Skills:

- Legal knowledge (understanding safety laws)

- Statistics (analyzing incident data, trends)

- System design (designing safety into processes)

Psychology (building safety culture, behavior change)

Soft Skills for Success

Communication:

- Explain safety concepts to workers at all levels

- Present data and recommendations to management

- Train large groups effectively

- Communicate safety policies clearly

- Listen to worker concerns

Leadership:

- Build safety culture where workers care about safety

- Influence without authority (safety team members may not report to you)

- Coach and mentor safety coordinators

- Lead by example (follow safety procedures yourself)

Problem-Solving:

- Investigate complex incidents

- Find root causes systematically

- Develop practical solutions

- Think about system improvements

Credibility & Integrity:

- Maintain consistent standards for all

- Follow up on every incident

- Demonstrate genuine commitment to safety

Build trust with workers and management

Salary Expectations for EHS Officer

EHS Coordinator / Junior EHS Specialist:

₹26,000 – ₹40,000/month

(Entry-level, support role)

EHS Officer / Health & Safety Officer:

₹40,000 – ₹60,000/month

(Primary responsibility for facility)

Senior EHS Officer / Safety Manager:

₹60,000 – ₹90,000/month

(Multiple facilities or large facility oversight)

EHS Manager / Director:

₹90,000 – ₹1,40,000/month

(Department leadership, strategy)

Why Salaries Grow in EHS:

- Liability: Safety failures cost companies enormously (lawsuits, fines, reputation)

- Regulatory: Increasing regulations make EHS role more critical

- Insurance: Good safety record reduces insurance premiums (company saves money)

- Specialization: EHS experts with deep industry knowledge command premium

International: Global companies need EHS directors who understand multiple regulatory regimes

How to Enter EHS

Path 1: Manufacturing Role + EHS Transition

- Start in manufacturing (any role: production, maintenance, engineering)

- Show interest in safety: Volunteer for safety committee, suggest improvements

- Complete OSHA training (40-hour course: ₹15,000-25,000)

- Pursue EHS certification (see below)

- Transition to EHS coordinator (₹30,000-42,000/month)

Path 2: Engineering/Science Background + EHS Training

- Have degree in engineering, environmental science, or related field

- Pursue EHS certifications (OSHA, IOSH, etc.)

- Enter EHS specialist role directly (₹35,000-48,000/month)

Path 3: EHS Specialized Degree

- Complete EHS degree or diploma (specialized programs available)

Enter EHS coordinator role (₹30,000-42,000/month)

Certifications That Boost EHS Career

Entry-Level Certifications:

- OSHA 30-Hour Course: Foundational, highly recommended

- Cost: ₹10,000-18,000, Duration: 30 hours (online/classroom)

- ROI: Essential for any EHS role

Professional Certifications:

- IOSH (Institution of Occupational Safety & Health) Managing Safely: +₹5,000-8,000/month

- Cost: ₹40,000-60,000, Duration: 3 days + self-study

- ROI: Internationally recognized, highly valued

- Certified Safety Professional (CSP): Advanced certification, +₹12,000-20,000/month

- Requires experience + exam

- Cost: ₹50,000-1,00,000

- ROI: Top-tier EHS credential; path to senior roles

Specialization Certifications:

- Certified Environmental Compliance Auditor (CECA): +₹8,000-12,000/month

- Risk Assessment Certification: +₹5,000-8,000/month

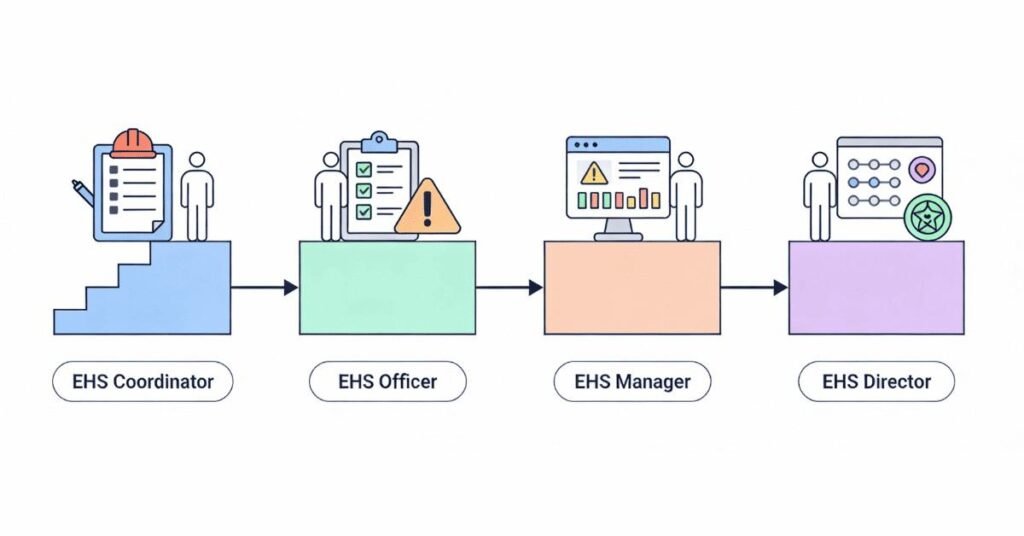

Career Progression: Coordinator to Director

Year 1: EHS Coordinator

- Support EHS programs, coordinate training

- Salary: ₹28,000-40,000/month

Year 2-3: EHS Officer

- Primary responsibility for facility safety

- Lead incident investigations

- Salary: ₹40,000-60,000/month

Year 4-5: Senior Officer / EHS Manager

- Oversee multiple facilities or large facility

- Develop safety strategy

- Team leadership

- Salary: ₹60,000-90,000/month

Year 6+: EHS Director

- Executive role, board-level responsibility

- Company-wide safety strategy

Salary: ₹90,000-1,40,000+/month

The Bottom Line: EHS is Non-Negotiable Career

Every facility needs EHS professionals. Companies are increasingly focused on safety and sustainability. Entry salary ₹28,000-42,000 → 5-year salary ₹60,000-90,000+. The work is meaningful (preventing injuries, protecting environment), strategically important, and growing.

If you care about worker safety and environmental protection, EHS is your fulfilling career path.