The Blue-Collar to White-Collar Transformation

Table of Contents

The Outdated Stereotype: Why Your Parents' View of Manufacturing is Wrong

Your parents probably have a specific image of manufacturing: hard manual labor, dirt, danger, limited earning potential. That image might have been accurate in 1995. It’s completely outdated in 2025.

The manufacturing world has undergone a metamorphosis. The old boundary between “blue-collar” workers (hands-on, manual labor) and “white-collar” workers (office-based, knowledge work) has blurred so thoroughly that it barely exists anymore.

Let me show you what this actually looks like in modern factories.

What Was the Old Manufacturing Model?

In traditional manufacturing (think: pre-2010), there was a clear divide:

Blue-Collar Workers:

- Assembly operators who assembled products manually

- Machine operators who ran equipment following written instructions

- Maintenance workers who fixed things after they broke

- Quality inspectors who visually checked products

- Typical salary: ₹10,000-20,000/month

- Typical advancement: Become a supervisor after 10+ years

- Work location: Factory floor, production area

White-Collar Workers:

- Engineers who designed systems (in offices, with blueprints)

- Managers who planned production (in offices, with paperwork)

- Accountants who tracked finances (in offices)

- Typical salary: ₹30,000-50,000/month

- Typical advancement: Become a manager relatively quickly

- Work location: Office buildings, away from production

These two groups rarely interacted. They had different entry requirements, different skill sets, and vastly different career trajectories. A person starting as an assembly operator almost never became an engineer.

The gap was huge. And it was fundamentally limiting.

How Industry 4.0 Shattered This Divide

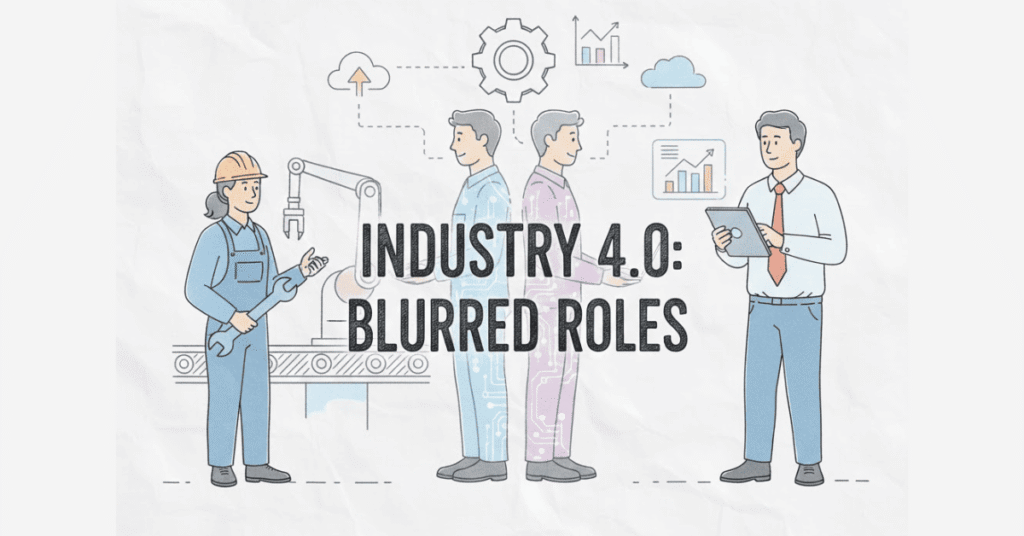

Now imagine bringing the Internet of Things, AI, cloud computing, and data analytics into that old system. What happens?

Suddenly, an assembly operator needs to understand data dashboards. A machine operator needs to interpret sensor readings. A maintenance worker needs to understand predictive analytics. These aren’t office skills—they’re being done on the factory floor by people formerly considered “just” blue-collar workers.

AI-powered quality systems mean QC isn’t about visual inspection anymore—it’s about understanding AI accuracy, troubleshooting algorithm errors, and making decisions based on system recommendations.

Robotics in assembly means operators are now programmers—they configure, debug, and optimize robot sequences.

Predictive maintenance means technicians need to understand data patterns, not just mechanical troubleshooting.

The roles haven’t disappeared; they’ve transformed. They’ve become hybrid roles that combine hands-on understanding with technology expertise.

Real Modern Manufacturing Role Examples: The Hybrid Effect

Example 1: The Modern Assembly Operator (2025 Version)

Old Assembly Operator (1995):

“Follow these written instructions, assemble the part using hand tools, place completed part in bin, move to next unit.”

Salary: ₹8,000/month, Advancement: Almost none

Modern Assembly Operator (2025):

“Follow work instructions on digital tablet, scan each completed product with QR code, report any quality issues to the tablet system, when tablet shows defect, photograph the issue using phone camera, document the cause in the system, receive alerts when inventory needs replenishment or equipment needs adjustment, collaborate with robotic arms by securing components in fixtures.”

Salary: ₹15,000-25,000/month, Advancement: Can move to Shift Supervisor or Quality Control roles

The work is still hands-on—assembling products. But now it requires digital literacy, quick problem-solving, and data entry. It’s becoming white-collar in terms of skills while remaining blue-collar in terms of location and nature.

Example 2: The Modern Machine Operator (2025 Version)

Old Machine Operator (1995):

“Turn on the machine, monitor it for errors, if something sounds wrong, call maintenance.”

Salary: ₹10,000/month, Advancement: Almost none

Modern Machine Operator (2025):

“Log into the machine’s control system with your credentials, load work orders from the central manufacturing execution system (MES), monitor production parameters on the touch screen, if anything deviates from set parameters, troubleshoot using decision trees on the system, document why the issue occurred, receive notifications if production falls behind schedule, communicate with quality systems to flag products for inspection, participate in daily team meetings using video conference.”

Salary: ₹20,000-30,000/month, Advancement: Can move to Shift Supervisor, Production Technician, or even Production Engineering roles

Same machine. Entirely different skill set. It now requires basic computer literacy, logical thinking, and communication skills—traditionally white-collar attributes.

Example 3: The Modern Quality Inspector (2025 Version)

Old QC Inspector (1995):

“Visually inspect products, count defects, report numbers at end of shift.”

Salary: ₹9,000/month, Advancement: Slow to supervisor role

Modern QC Inspector (2025):

“Monitor AI-powered vision system outputs, verify system accuracy by spot-checking flagged products, input inspection results into the quality management system, generate daily quality reports with AI assistance, identify quality trends using provided analytics, suggest process improvements when patterns emerge, coordinate with production team to prevent recurring defects, maintain documentation for ISO compliance.”

Salary: ₹25,000-40,000/month, Advancement: Can move to Quality Executive, Quality Specialist, or Quality Manager roles

Notice the difference? The inspector’s role hasn’t eliminated; it’s evolved. And the salary, responsibilities, and advancement opportunities have improved dramatically. This person is now doing analytical work (white-collar) while still being based on the production floor.

The Earnings Transformation: The Blue-Collar Premium

Here’s something nobody talks about: modern manufacturing blue-collar jobs now earn what white-collar office jobs used to earn.

In advanced manufacturing facilities using Industry 4.0 technologies, skilled production operators earn ₹25,000-35,000 per month. That’s comparable to or exceeding many office-based IT support roles or administrative positions.

Why? Because these operators now require:

- Technical literacy (computers, systems, software)

- Problem-solving abilities (analysis, decision-making)

- Communication skills (reporting, team coordination)

- Responsibility (their decisions directly impact production quality)

They’re not just pushing buttons; they’re running systems. Companies pay accordingly.

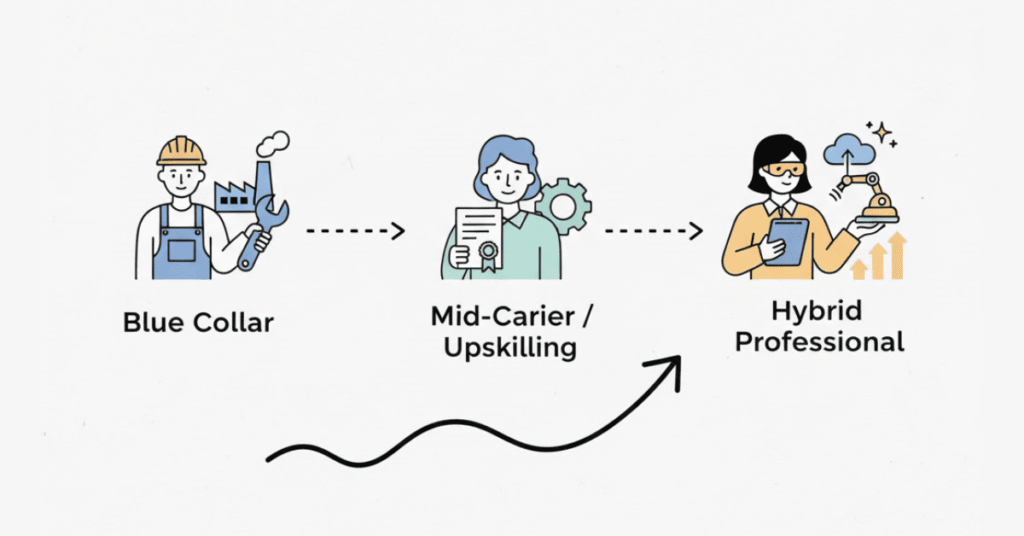

The Real Career Implication:

A fresher who starts as a modern assembly operator in 2025 can earn ₹15,000-25,000/month right away. With 2-3 years of experience and some additional certifications, they can move to roles paying ₹35,000-50,000/month. There’s no need to leave the production floor or get additional formal degrees. The opportunity is right there.

Hands-On + Thinking = Hybrid Career Advantage

Modern manufacturing values people who can do two things simultaneously:

- Understand the Physical Process

- How things are actually made

- What can go wrong in production

- How to spot quality issues

- Practical troubleshooting

- How things are actually made

- Understand the Digital Systems

- How systems collect and analyze data

- How to interpret dashboards

- How to use software tools

- How to make data-driven decisions

- How systems collect and analyze data

People who combine both are incredibly valuable. They’re not just doing work; they’re optimizing systems. They understand the why, not just the how.

This hybrid skill set is why:

- A production operator with basic IT skills can earn 40% more than one without

- A maintenance technician who understands predictive maintenance systems advances faster than one who doesn’t

A quality inspector who can interpret data trends becomes a quality manager sooner

The Blurred Line: True Story

Meet Rajesh, a real example from a manufacturing facility:

2015: Rajesh joined as an assembly operator. His job: assemble electronic components on a circuit board. Salary: ₹10,000/month.

2018: The facility adopted Industry 4.0 technologies. Assembly moved partially to automated systems, but human oversight remained critical. Rajesh’s role evolved. He now programmed the robots, verified their work, and diagnosed problems. Salary: ₹25,000/month.

2021: Rajesh took a short online course in data analysis. He started analyzing production data to identify patterns. He discovered that defects correlated with specific environmental conditions. He suggested changes. They were implemented. Production improved by 8%. Salary: ₹35,000/month.

2024: Rajesh became a Production Technician supervising 3 assembly lines and training new operators on the systems. Salary: ₹50,000/month.

2025: He’s considering moving to a Production Engineer role (white-collar by traditional definition). Potential salary: ₹60,000+/month.

Was Rajesh ever a “blue-collar” worker in the traditional sense? He started assembling components. Did he ever transition to “white-collar”? He started doing analysis and optimization. The boundary no longer exists for him—he’s both, simultaneously.

Why This Matters for Your Career Decision

If you’re hesitant about manufacturing because you think it’s “just” blue-collar work with limited prospects, reconsider.

Modern manufacturing offers:

- Immediate earning potential comparable to office jobs

- Hands-on + thinking combination making work more engaging than pure office routine

- Clear advancement paths without needing to move away from the production environment

- Technology exposure keeping your skills current and relevant

- Practical impact seeing the direct results of your work

You’re not choosing between “blue-collar” work and “white-collar” work. You’re choosing a hybrid modern career that leverages both physical understanding and analytical thinking.

The Bottom Line: The Future is Hybrid

The manufacturing industry’s evolution shows us something important about the future of work: the distinction between blue-collar and white-collar is becoming obsolete.

Modern work demands technical literacy, problem-solving, and communication skills regardless of location. A technician on the factory floor now uses technology that office workers used exclusively 20 years ago.

If you’re a person who enjoys working with your hands but also likes solving problems and using technology, manufacturing in 2025 is tailor-made for you. You won’t be confined to repetitive manual labor. You’ll be using your full capabilities—physical, analytical, and technical—all at once.

That’s the manufacturing career opportunity of 2025: not just a job, but a genuinely interesting, skill-building, financially rewarding career path.