Manufacturing Logistics Coordinator—The Supply Chain Backbone

Table of Contents

The Person Who Ensures Materials Flow: Logistics Coordinator

Manufacturing can’t happen without materials. The right components, at the right time, in the right quantity, at the right location. Logistics coordinators make this happen.

They earn ₹22,000-35,000/month as entry-level coordinators, advancing to ₹55,000-90,000+/month within 6-8 years in management roles.

What Logistics Coordinators Actually Do:

Priya, Manufacturing Logistics Coordinator at an automotive component facility:

Monday: Material Planning

Production needs 500 units of Component X this week. Priya:

- Reviews production schedule (when are parts needed?)

- Checks current inventory (how many do we have in stock?)

- Finds: Have 200 in stock, need 500, so need 300 more

- Checks supplier lead time (how long does supplier take to deliver?)

- Finds: Supplier takes 3 days

- Places order today (Tuesday delivery ensures Tuesday evening stock update)

- Sets delivery expectation with production (parts arrive Tuesday, ready for Wednesday production)

- Documents: Records order in system

Wednesday: Receiving & Inspection

Components arrive from supplier. Priya:

- Receives delivery (verifies quantity received matches order quantity)

- Checks quality (inspects for damage, defects)

- Counts units: 300 received, correct

- Checks quality: All items acceptable (no damage,

- all specifications met)

- Records in inventory system (now shows 500 in stock)

- Directs delivery to storage location

- Updates production: “Components are ready”

Thursday: Inventory Optimization

Weekly review of inventory levels across facility:

- Component A: 50 in stock (sufficient, using 10/day)

- Component B: 200 in stock (excess, using 5/day—could cause capital to be tied up)

- Component C: 5 in stock (risky, need 8/day—could run out)

Actions:

- Component B: Delay next order (currently over-stocked)

- Component C: Place emergency order (need to increase safety stock)

- Orders raw materials: Supplier takes 5 days; order today for delivery next week

Friday: Cost Optimization

Part of logistics is controlling costs. Priya:

- Reviews supplier quotes: Current supplier charges ₹100/unit; new supplier quotes ₹94/unit

- Quality equivalent? Yes, new supplier meets all specs

- Lead time equivalent? Yes, both 3 days

- Risk? New supplier is unproven, but has capacity

- Recommendation: Switch 50% of orders to new supplier (reduce cost, maintain safety by using two suppliers)

- Management approves

- Updates procurement records

Ongoing: Order Tracking

- Tracks all outstanding orders (status, expected delivery)

- Resolves delivery issues (order late? Communicates with supplier, adjusts plans)

- Handles emergency orders (production runs short on material, Priya sources quickly)

- Maintains supplier relationships

Result: Facility maintains just-in-time inventory (minimal storage needed), zero stock-outs (production never delayed by material), 5% cost reduction through supplier optimization.

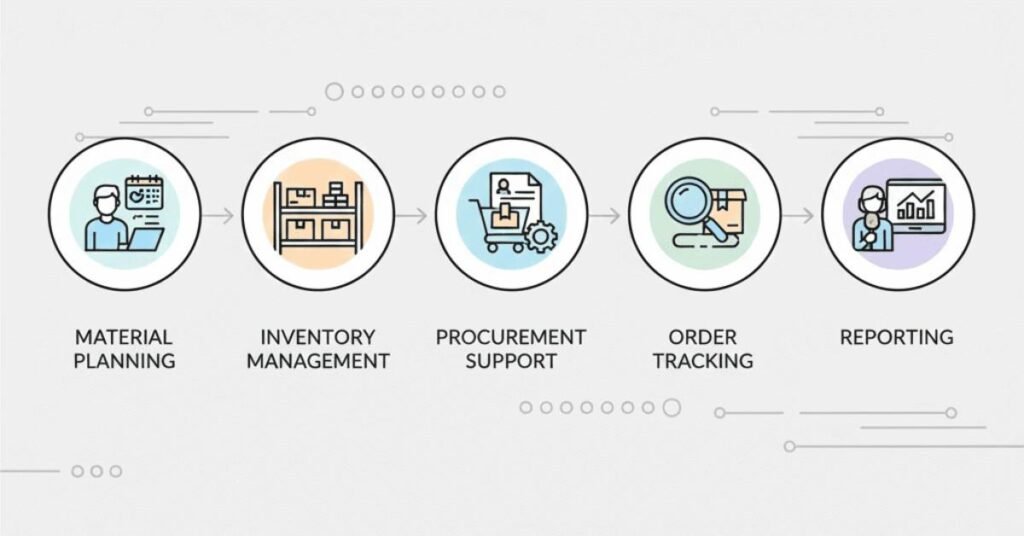

Key Responsibilities of Logistics Coordinator

Material Planning (25%):

- Forecast material needs based on production schedule

- Plan orders (quantities, timing)

- Coordinate with suppliers

- Manage lead times

- Ensure material availability

Inventory Management (25%):

- Track inventory levels

- Receive and inspect materials

- Organize storage

- Minimize excess inventory

- Prevent stockouts

Procurement Support (20%):

- Obtain supplier quotes

- Compare costs and quality

- Manage supplier relationships

- Handle purchase orders

- Track payment and invoicing

Order Tracking & Problem-Solving (20%):

- Track outstanding orders

- Resolve delivery issues

- Handle emergency orders

- Communicate with suppliers

- Adjust plans when needed

Documentation & Reporting (10%):

- Maintain inventory records

- Generate reports (inventory levels, supplier performance, costs)

- Document orders and deliveries

Ensure data accuracy

Skills You Need

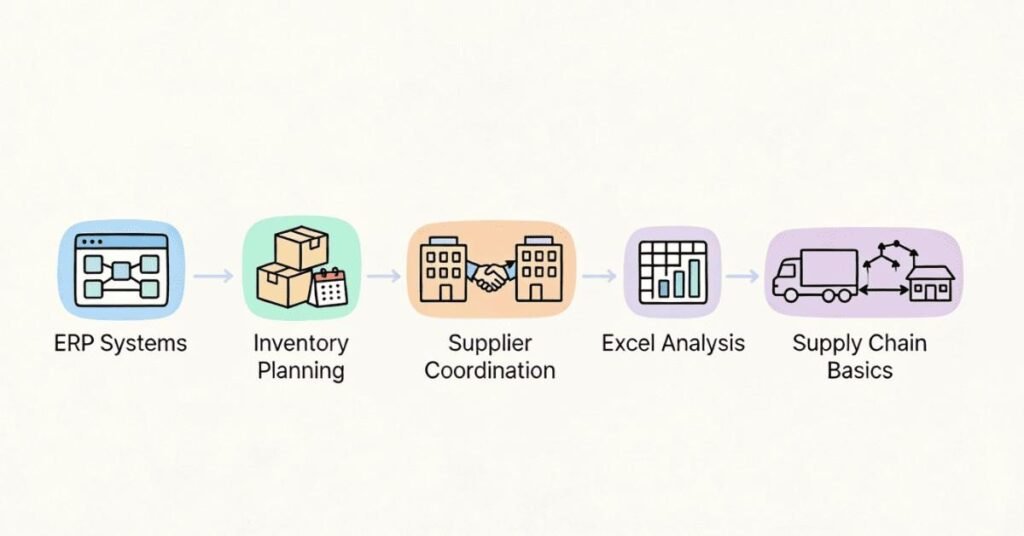

Technical Skills:

- Inventory Management Systems (Critical)

- ERP systems (SAP, Oracle, Microsoft Dynamics)

- Inventory tracking software

- Barcode and RFID systems

- Warehouse management systems

- Why: Inventory management is computerized; must use systems proficiently

- Learning: System-specific training (30-50 hours)

- Supply Chain Basics (Important)

- Material planning concepts (MRP, forecasting)

- Just-in-time (JIT) principles

- Safety stock calculation

- Lead time management

- Why: Understanding these improves planning

- Learning: Supply chain management courses (30-50 hours)

- Procurement Knowledge (Important)

- Supplier evaluation

- Cost analysis

- Quality standards

- Contract understanding

- Why: Procurement decisions impact costs and quality

- Learning: Procurement courses (20-30 hours)

- Logistics & Transportation (Important)

- Shipping and delivery methods

- Route optimization

- Packaging for protection

- Cost analysis of transportation

- Why: Moving materials efficiently is part of logistics

- Learning: Logistics courses (20-30 hours)

- Excel & Data Analysis (Important)

- Spreadsheet proficiency

- Pivot tables and analysis

- Cost calculations

- Trend analysis

- Why: Much logistics work involves data

- Learning: Excel training (20-40 hours)

Soft Skills:

- Communication: Interact with production team, suppliers, management

- Problem-solving: Resolve supply issues, optimize plans

- Attention to detail: Accurate inventory crucial

- Negotiation: Negotiate with suppliers for best cost/quality

Organization: Manage multiple orders, deadlines simultaneously

Salary Expectations for Manufacturing Logistics

Logistics Coordinator / Material Handler:

₹22,000 – ₹35,000/month

(Entry-level, coordinating role)

Senior Logistics Coordinator:

₹35,000 – ₹50,000/month

(More responsibility, possibly supervising coordinators)

Logistics Supervisor / Team Lead:

₹48,000 – ₹70,000/month

(Leading small team, planning multiple areas)

Logistics Manager:

₹70,000 – ₹1,00,000/month

(Department leadership, multiple facilities possible)

Supply Chain Manager / Director:

₹1,00,000 – ₹1,50,000+/month

(Executive leadership, company-wide supply chain strategy)

Why Salaries Grow:

- Impact on costs: Logistics decisions directly affect company profitability (material costs are major expense)

- Business criticality: Supply chain failures halt production (very expensive)

- Complexity increases: Senior roles manage more complex supply chains

Specialization: Deep supply chain expertise commands premium

How to Enter Logistics

Path 1: Any Degree + Logistics Training

- Complete any bachelor’s degree (economics, commerce, engineering, IT)

- Pursue logistics or supply chain certification (see below)

- Enter logistics coordinator role (₹24,000-35,000/month)

Path 2: Diploma + Specialization

- Complete logistics or commerce diploma (2 years)

- Enter logistics coordinator role (₹22,000-32,000/month)

Path 3: Manufacturing Background + Logistics Training

- Work in manufacturing (production, maintenance, quality)

- Show interest in supply chain

- Pursue logistics training (online courses, certifications)

- Transition to logistics coordinator (your manufacturing knowledge is valuable)

Salary: Often higher: ₹28,000-38,000/month

Certifications That Boost Logistics Career

Entry-Level Certifications:

- APICS CSCP (Certified Supply Chain Professional): Comprehensive supply chain knowledge

- Cost: ₹50,000-80,000, Duration: 3-6 months

- ROI: High; APICS certification globally recognized

- Benefit: +₹6,000-10,000/month salary

- Six Sigma Green Belt (applied to logistics): Process optimization

- Cost: ₹20,000-35,000, Duration: 4-6 weeks

- Benefit: +₹4,000-8,000/month salary

Advanced Certifications:

- APICS CPIM (Certified in Production and Inventory Management): Advanced

- Cost: ₹70,000-1,00,000, Duration: 6-12 months

- ROI: Very high; path to manager roles

- Benefit: +₹12,000-18,000/month salary

- APICS APICS+CSCP (Advanced Planning & Scheduling): Specialized

- Cost: ₹80,000-1,20,000

- Benefit: +₹15,000-20,000/month salary

MBA in Logistics/Supply Chain:

- Duration: 2 years (full-time) or 3 years (part-time)

- Cost: ₹5,00,000-15,00,000

- ROI: Excellent if pursuing management roles

- Benefit: +₹25,000-40,000/month salary

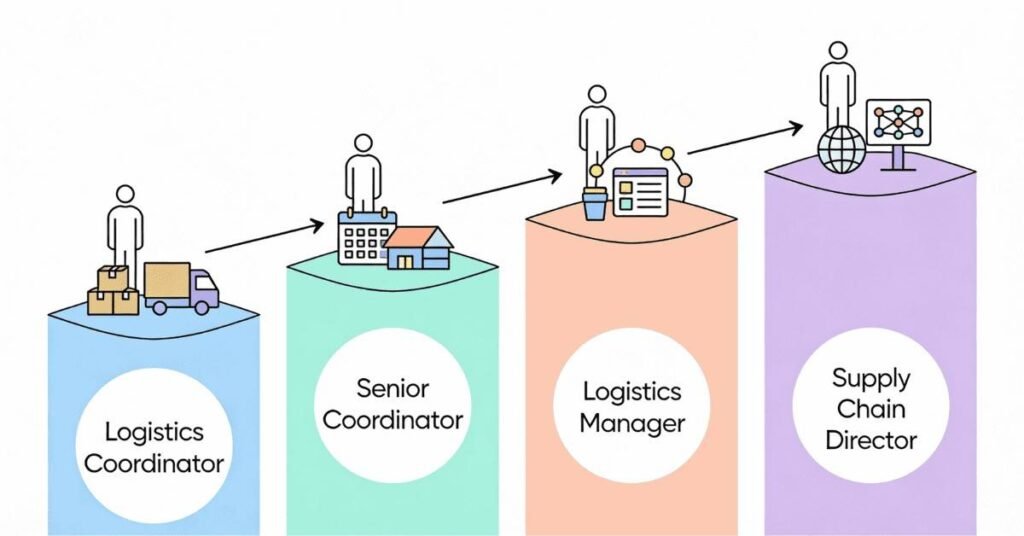

Career Progression: Coordinator to Director

Year 1: Logistics Coordinator

- Support material planning, supplier coordination

- Salary: ₹24,000-35,000/month

Year 2-3: Senior Coordinator

- Lead specific areas of supply chain

- Mentor junior coordinators

- Salary: ₹35,000-48,000/month

Year 4-5: Supervisor / Team Lead

- Oversee team of coordinators

- Manage section of supply chain

- Salary: ₹48,000-70,000/month

Year 6-8: Logistics Manager

- Department leadership

- Company-wide supply chain oversight

- Strategic planning

- Salary: ₹70,000-1,00,000/month

Year 8+: Supply Chain Director / VP

- Executive leadership

- Board-level responsibility

- Strategic vision

- Salary: ₹1,00,000-1,50,000+/month

Why Logistics is Underrated Career

Logistics coordinators are often overlooked—their work is behind-the-scenes. But manufacturing literally stops without materials. Logistics professionals are essential, valued, and compensated accordingly.

Entry salary ₹24,000-35,000 → 5-year salary ₹50,000-70,000+. Clear advancement path. Meaningful work (enabling production). Good job security.

If you like planning, problem-solving, and ensuring smooth operations, logistics is your career.